Steve Berglund

| Foundry

Pattern Artist

Foundries

Foundries do "Sand Casting" using the original Patterns and Molds to create metal products. Here are a few pictures from a typical foundry showing the basics of the process.

Bobcat to load the sand into the hopper

Aluminum bars to be melted in the cooker

Dipping Into the Hot Cooker

Loading the sand in the mold box

Setting the Mold Box in place

The sand drops down from the top

Laying the top of the mold box onto the botom

Laying the Core in the sand mold

Pouring aluminum into the Mold

Pouring the hot aluminum

Carrying the new HOT part

Knocking the sand loose

Finished Parts

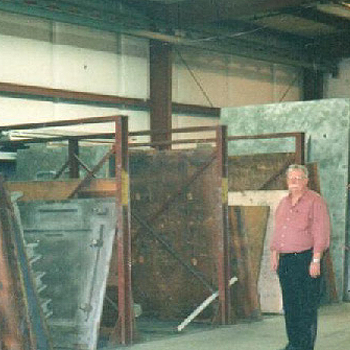

Sluice Gate Patterns used to control water flow in canals at Waterman in Exeter.

Twelve foot high Lathe used to cut round patterns at Waterman in Exeter.

Cooling Rail to cool the newly forged parts.

Peabody Floway Picture 1974.